- winspireadmin

- May 28, 2024

Introduction

In today’s fast-paced business environment, efficient warehouse management is crucial for the success of any company. However, many businesses face numerous challenges in managing their warehouses effectively. This article explores how Enterprise Resource Planning (ERP) software integrated with a Warehouse Management System (WMS) can address some of the most common warehouse management issues.

Understanding Common Warehouse Management Challenges

1. Inaccurate Inventory Counts

Accurate inventory management is essential for optimising warehouse operations and meeting customer demands. However, manual inventory counting processes are prone to errors, leading to discrepancies between recorded and actual stock levels.

2. Inefficient Picking Processes

Inefficient picking processes can result in delays in order fulfilment, leading to dissatisfied customers and increased operational costs. Traditional methods relying on paper-based systems or basic inventory tracking software often lack the speed and accuracy required for efficient picking.

3. Redundant Manual Processes

Many warehouses still rely heavily on manual processes for tasks such as order processing, inventory tracking, and data entry. These manual processes are not only time-consuming but also prone to errors, leading to inefficiencies and increased labour costs.

4. Issues with Employee Retention

High turnover rates among warehouse staff can disrupt operations and increase training costs. Warehouse employees may become frustrated with outdated systems and manual processes, decreasing job satisfaction and higher turnover. Implementing automation in warehouse operations can enhance employee retention rates. A recent research study carried out by Lucas Systems (Lucas Systems specialises in warehouse optimisation solutions) found that about 75% of warehouse workers are open to considering job offers from other companies, even if the compensation is lower, as long as the new opportunity offers technology that streamlines their tasks.

5. Lack of Quality Control

Maintaining quality control standards is essential to ensure customer satisfaction and minimising the risk of returns or recalls. However, without proper systems in place, warehouses may struggle to track product quality throughout the supply chain, leading to costly errors and reputational damage.

The Role of ERP and WMS Integration

1. Real-Time Inventory Visibility

By integrating ERP software with a WMS, businesses can achieve real-time visibility into their inventory levels. This allows for more accurate demand forecasting, reduced stockouts, and improved order fulfilment rates.

2. Streamlined Picking Processes

WMS integration enables the automation of picking processes, optimising warehouse layout and minimising travel time. With features such as pick-to-light and voice-directed picking, employees can fulfill orders more quickly and accurately

3. Automation of Manual Tasks

ERP-WMS integration automates repetitive manual tasks, such as data entry and order processing, reducing the likelihood of errors and freeing up staff to focus on higher-value activities.

4. Enhanced Employee Engagement

Modern ERP and WMS solutions are user-friendly and intuitive, improving employee satisfaction and reducing turnover. Access to real-time data and streamlined processes empowers warehouse staff to perform their jobs more efficiently.

5. Improved Quality Control

Integration between ERP and WMS systems facilitates end-to-end traceability, allowing businesses to track products from receipt to shipment. This enhances quality control processes, reducing the risk of errors and ensuring compliance with industry regulations.

Key Features of an Integrated ERP-WMS Solution:

1. Real-time Inventory Management:

- Benefits of Real-time Tracking: Imagine having a bird’s eye view of your inventory 24/7. Real-time tracking allows you to monitor stock levels, movement, and location instantaneously. This means you can make informed decisions on the fly, reducing the guesswork and enhancing accuracy.

2. User-friendly Interfaces:

- Intuitive Navigation: User-friendly interfaces make it easy for warehouse staff to navigate the system and perform tasks efficiently. Intuitive design and clear instructions reduce training time and minimise errors, improving overall productivity.

- Accessibility: User-friendly interfaces are accessible from various devices, including desktop computers, tablets, and mobile phones. This flexibility allows warehouse staff to access the system from anywhere, at any time, enhancing collaboration and responsiveness.

3. Robust Quality Control Capabilities:

- Ensuring Product Integrity: Robust quality control capabilities ensure that products meet the highest standards of quality and safety before they leave the warehouse. This includes checks for damage, expiration dates, and compliance with regulatory requirements.

- Preventing Costly Errors: By catching quality issues early in the process, robust quality control capabilities prevent costly errors such as shipping the wrong items or sending out defective products. This protects your reputation and bottom line.

4. Seamless Data Flow:

- Real-time Data Synchronisation: An integrated ERP-WMS solution ensures real-time data synchronisation between the systems. This means that information such as inventory levels, order status, and shipment details are always up to date, reducing the risk of errors and discrepancies.

5. Inventory Management:

- Accurate Inventory Tracking: With integrated systems, you can achieve precise inventory tracking. The WMS component manages the physical aspects of inventory, while the ERP system handles the financial and planning aspects, ensuring that inventory levels are always accurate.

- Automated Stock Replenishment: The integration enables automated stock replenishment. When inventory levels fall below a certain threshold, the system can automatically generate purchase orders, ensuring that stock levels are maintained without manual intervention.

6. Order Fulfilment:

- Streamlined Order Processing: Integrated ERP-WMS solutions streamline order processing by automating workflows from order receipt to fulfilment. This reduces processing times and increases order accuracy.

- Enhanced Picking and Packing: The WMS optimises picking and packing operations by using algorithms to determine the most efficient routes and methods. This results in faster and more accurate order fulfilment.

7. Warehouse Optimisation:

- Space Utilisation: An integrated system helps in better space utilisation within the warehouse. It can analyse storage patterns and suggest optimal layouts, making the best use of available space.

- Efficient Resource Allocation: By integrating resource planning and warehouse management, businesses can ensure that labour and equipment are used efficiently. This reduces downtime and increases productivity.

8. Improved Accuracy:

- Reduced Human Errors: Automation of data entry and synchronisation between systems minimises the chances of human errors, leading to more reliable and accurate operations.

- Enhanced Data Accuracy: With a single source of truth, data accuracy is significantly improved. This means better decision-making and fewer operational hiccups.

9. Enhanced Reporting and Analytics:

- Real-time Reporting: Integrated systems provide real-time reporting capabilities. Managers can access up-to-date information on inventory, orders, and other key metrics, enabling timely and informed decisions.

- Data-Driven Decision-Making: Advanced analytics tools can analyse data from both ERP and WMS, providing insights that help in optimising operations and planning.

10. Scalability and Flexibility:

- Adapting to Business Growth: As your business grows, an integrated ERP-WMS solution can scale with it. The system can handle increased volumes and more complex operations without a hitch.

- Customisable Workflows: Businesses can customise workflows to meet their specific needs. This flexibility ensures that the system can adapt to different industries and operational requirements.

11. Better Customer Service:

- Faster Order Processing: With streamlined processes and real-time data, orders are processed faster, leading to shorter delivery times and happier customers.

- Improved Order Accuracy: Accurate inventory and efficient order fulfilment mean fewer errors in order processing, resulting in improved customer satisfaction.

12. Cost Efficiency:

- Reduced Operational Costs: Automation and optimised workflows reduce the need for manual labour and decrease operational costs. This leads to better margins and a more efficient operation.

- Better Resource Management: Integrated systems ensure that resources are used efficiently, reducing waste and improving overall operational efficiency.

13. Compliance and Security:

- Regulatory Compliance: Integrated systems help in maintaining compliance with industry regulations by providing accurate and timely data for audits and reports.

- Data Security: Data security is enhanced through centralised management and robust security measures, protecting sensitive information from breaches.

Conclusion

Integrating ERP software with a Warehouse Management System is a strategic move for businesses aiming to tackle common warehouse management issues. This powerful combination enhances inventory accuracy, streamlines order fulfilment, optimises space utilisation, improves labour management, provides real-time data, and simplifies compliance and reporting. Incorporating ERP software with a Warehouse Management System offers a comprehensive solution to the common challenges faced in warehouse management. By addressing issues such as inaccurate inventory counts, inefficient picking processes, redundant manual tasks, employee retention, and quality control, businesses can optimise their warehouse operations, improve customer satisfaction, and gain a competitive edge in the market. If you’re facing warehouse management challenges, consider exploring ERP-WMS integration to transform your operations and stay ahead of the competition.

Don’t let inaccurate inventory counts, inefficient picking processes, and redundant manual tasks hold your business back any longer. Contact our experts to optimise your warehouse management and stay ahead of the competition!

Watch our client testimonial videos to see how we helped them improve warehouse management

FAQ

FAQ

1. How does ERP-WMS integration improve inventory accuracy?

ERP-WMS integration provides real-time visibility into inventory levels, reducing the likelihood of discrepancies between recorded and actual stock counts.

2. Can ERP-WMS integration help reduce labour costs?

Yes, by automating manual tasks and streamlining processes, ERP-WMS integration can help reduce labour costs associated with warehouse operations.

3. What are the key features to look for in an integrated ERP-WMS solution?

Key features include real-time inventory visibility, automated picking processes, user-friendly interfaces, and robust quality control capabilities.

4. How can ERP-WMS integration enhance order fulfilment rates?

By optimising picking processes and reducing order processing times, ERP-WMS integration can improve order fulfilment rates and reduce lead times.

5. Is ERP-WMS integration suitable for small businesses?

Yes, ERP-WMS integration can benefit businesses of all sizes by improving operational efficiency, reducing costs, and enhancing customer satisfaction.

ERP-WMS integration provides real-time visibility into inventory levels, reducing the likelihood of discrepancies between recorded and actual stock counts.

Yes, by automating manual tasks and streamlining processes, ERP-WMS integration can help reduce labour costs associated with warehouse operations.

Key features include real-time inventory visibility, automated picking processes, user-friendly interfaces, and robust quality control capabilities.

By optimising picking processes and reducing order processing times, ERP-WMS integration can improve order fulfilment rates and reduce lead times.

Yes, ERP-WMS integration can benefit businesses of all sizes by improving operational efficiency, reducing costs, and enhancing customer satisfaction.

ERP-WMS integration provides real-time visibility into inventory levels, reducing the likelihood of discrepancies between recorded and actual stock counts.

Yes, by automating manual tasks and streamlining processes, ERP-WMS integration can help reduce labour costs associated with warehouse operations.

Key features include real-time inventory visibility, automated picking processes, user-friendly interfaces, and robust quality control capabilities.

By optimising picking processes and reducing order processing times, ERP-WMS integration can improve order fulfilment rates and reduce lead times.

Yes, ERP-WMS integration can benefit businesses of all sizes by improving operational efficiency, reducing costs, and enhancing customer satisfaction.

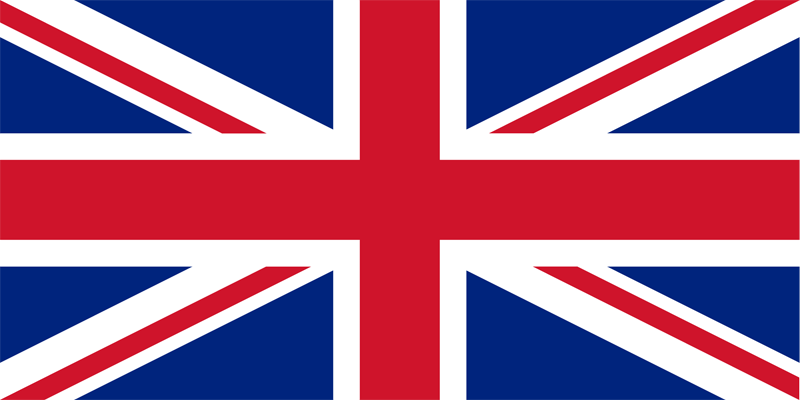

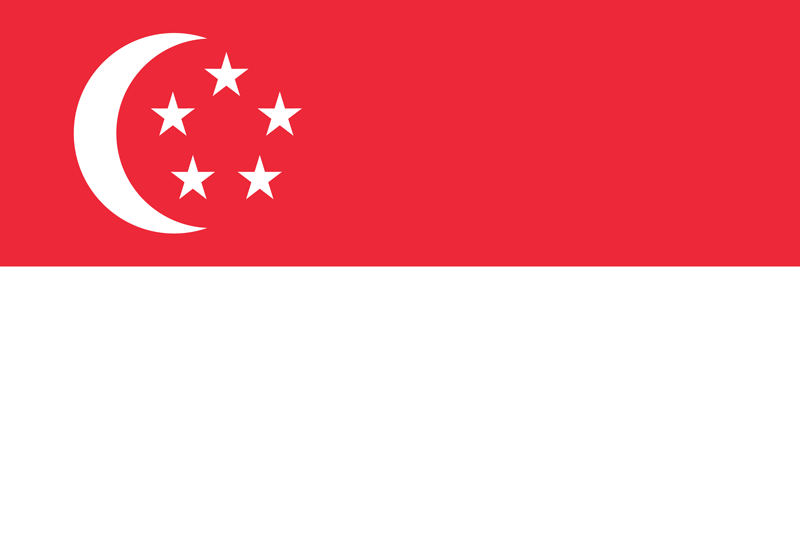

Singapore

Singapore